Always take your car to a Z specialist for this kind of job. I would not trust most Nissan dealers as these cars have been off their showroom floors for too long.

There is not much here on the "how to" part since I lacked the time, space, tools, and most importantly the skills to pull my engine and install new turbos. Finding someone who knows these cars is crucial for this kind of work. There are a handful of people to whom I would entrust my Z for this job. One of them is Bernie Bilski in Alexandria, VA, three hours south of me. The kind of work Bernie does is hard to find at any price.

Bernie obsesses on details, uses a torque wrench to excess, will die cut any old fastener that has less than perfect threads, and added many improvements that I had not thought of. He also had every conceivable OEM nut and bolt already on hand. Triple the amount of time Bernie tells you it will take to get anything done and you will be close.

I had been slowly collecting parts for over four years for my first engine pull. I was in no real hurry because my car ran perfectly, and I was hesistant to perform major surgery on a healthy patient. Then I waited over a year for certain exhaust manifolds to come to market, and for the downpipes I wanted to morph into their final form.

The main reason for my engine pull was to upgrade to more powerful turbos. The factory service manual described a procedure for changing the turbos with the engine still in the car. Anyone who has tried this will tell you that the easier way is to pull the engine. Plus, I was also having new exhaust manifolds installed which required an engine pull. This also made installing the new electrical engine harness much easier, and I was due for a new clutch (my fourth). I had some oil leaks and other housekeeping issues that would be much easier to work on with the engine out.

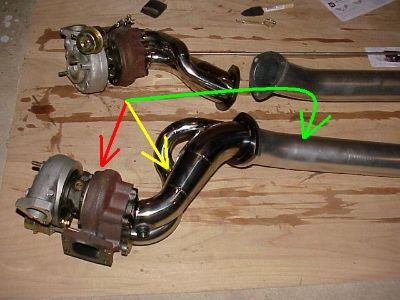

These are a pair of JWT 530 BB turbos. IMHO, the best all around, streetable turbo for the z32. These are a pair of JWT 530 BB turbos. IMHO, the best all around, streetable turbo for the z32.

Here is a 3" expansion downpipe (yellow) hooked up to the above turbo (red) and a 3" midpipe (green). The stock exhaust is 2.5". Here is a 3" expansion downpipe (yellow) hooked up to the above turbo (red) and a 3" midpipe (green). The stock exhaust is 2.5".

Here were all the parts I had waiting to be installed. My exhaust manifolds are not shown.

Larger photos here, Larger photos here,

and here. and here.

A. New turbos, JWT 530 BB

B. Downpipes SS, split, 3"

C. Midpipes, 3", w/ high flow cats

D. Engine mounts, OEM

E. South Bend Feramic clutch Stage V

F. Pilot bushing, OEM

G. Tension rods w/ 3-piece ES bushings

H. Intercooler hoses, Stillen, silicone

I. Union fittings for clutch line, upper bleed delete

J. Gaskets and bolts for DP’s, MP’s

K. Oil feed lines for turbos, SS

L. Throw-out bearing, OEM

M. Gaskets, 5-bolt for turbos-DP’s

N. Pivot ball, chromoly

O. Turbo boost gauge

P. Alternator harness

Q. Clutch hard line

R. Power steering hose

S. Engine EFI harness

T. PVC hoses

U. Engine harness clips

V. Detonation sensor harness

W. Power steering suction hose

X. Boost jets / welding tips

After the turbos, these Mike Smith manifolds with Jet Hot coating were the second most expensive pieces installed.

All of the above parts loaded in my Z hatch and passenger seat for the trip to Bernie's house. All of the above parts loaded in my Z hatch and passenger seat for the trip to Bernie's house.

Jacked, in the beginning. Jacked, in the beginning.

Bottom comes out first. Bottom comes out first.

Bernie kneeling on engine, cutting loose old engine harness. Bernie kneeling on engine, cutting loose old engine harness.

Ash and Spence, lifting engine out. Ash and Spence, lifting engine out.

Spencer holding engine in air with one hand. Spencer holding engine in air with one hand.

Very grimy empty engine bay that Ashley later got wonderfully clean. Very grimy empty engine bay that Ashley later got wonderfully clean.

Bernie in his element. Bernie in his element.

old EFI harness cut free old EFI harness cut free

Lots of work accomplished by the time I returned to Bernie's garage. New seals and gaskets everywhere on the engine. The plenum had been pulled, timing belt changed, more details than I can remember. My old turbos were already sold and gone. My new exhaust manifolds were installed. My engine was on a stand.

Front of engine, new timing belt. Front of engine, new timing belt.

The new passenger side exhaust manifold, installed. The new passenger side exhaust manifold, installed.

Driver side exhaust manifold. Driver side exhaust manifold.

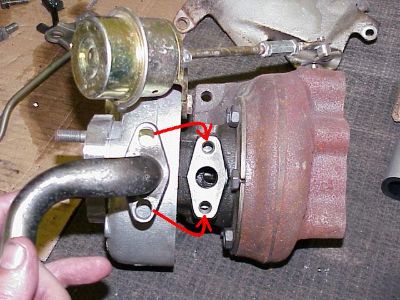

Back center of engine. New detonation sensor harness shown at red arrows. The EGR was deleted, used to be mounted at the green bolts. . Back center of engine. New detonation sensor harness shown at red arrows. The EGR was deleted, used to be mounted at the green bolts. .

Not exactly a show car but the engine bay was a lot cleaner than before. Not exactly a show car but the engine bay was a lot cleaner than before.

M snazzy new red silicone water heater hoses. The round hole in the firewall to the left of them is where the new electrical engine harness gets poked through to connect to the ECU. M snazzy new red silicone water heater hoses. The round hole in the firewall to the left of them is where the new electrical engine harness gets poked through to connect to the ECU.

My alternator covered with what Ashley called "Black Velvet" or an accumulation of oil and power steering fluid. Amazing the thing still worked. My alternator covered with what Ashley called "Black Velvet" or an accumulation of oil and power steering fluid. Amazing the thing still worked.

Same alternator after being cleaned up and rebuilt by my friends at Fleet Electric. My headlights got brighter, stereo performed better, and new life was breathed into my battery. Same alternator after being cleaned up and rebuilt by my friends at Fleet Electric. My headlights got brighter, stereo performed better, and new life was breathed into my battery.

New engine mounts required a little grinding for the turbos to fit, New engine mounts required a little grinding for the turbos to fit,

as did the bolt holes on the original oil feed lines for the new turbos. as did the bolt holes on the original oil feed lines for the new turbos.

I love my JUN chromoly flywheel. I'm on my fourth clutch with this flywheel, shown here freshly turned. I love my JUN chromoly flywheel. I'm on my fourth clutch with this flywheel, shown here freshly turned.

Bernie & Ash performing two harness mods: direct wire to PTU which eliminated 2 PTU subharness; and power-kill to injectors when ignition is off. Bernie & Ash performing two harness mods: direct wire to PTU which eliminated 2 PTU subharness; and power-kill to injectors when ignition is off.

Spence and Bern installing the turbos. Spence and Bern installing the turbos.

View from above of my new 3-piece Energy Suspension bushings in my tension rods. Somebody's ass in jeans under the car. View from above of my new 3-piece Energy Suspension bushings in my tension rods. Somebody's ass in jeans under the car.

weird clamp weird clamp

Engine put back in, new turbos, new downpipes, new clutch, same old transmission, new three inch midpipes.

Passenger side DP, new turbo, SS oil line. Passenger side DP, new turbo, SS oil line.

New Stillen red intercooler hoses. I do not recommend using metal intercooler hardpipes, which among other things will double the number of clamps. New Stillen red intercooler hoses. I do not recommend using metal intercooler hardpipes, which among other things will double the number of clamps.

Take Amtrak from Harrisburg to Philadelphia. Switch trains to Alexandria. Catch REX Metro bus to Bernies house. Pick up car.

|